Our Mission

Rasmussen Designs delights customers with robust, innovative and profitable solutions that minimize product support issues–all at a fixed cost.

Our Work

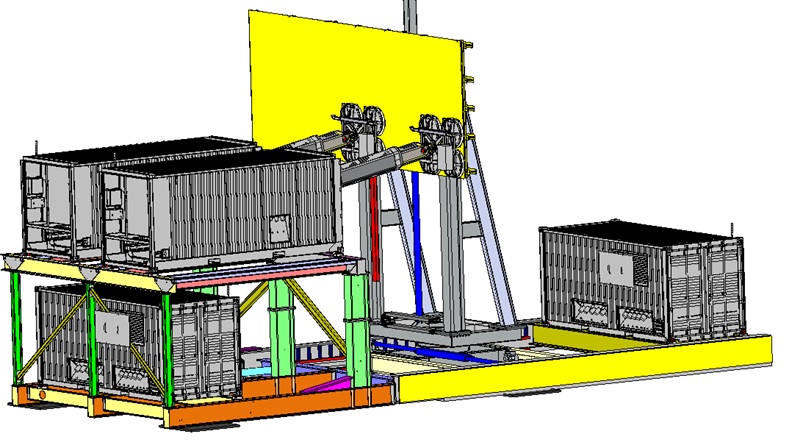

Mobile Equipment Design

Design, built and tested a vast array of mobile equipment including Insulate MEWPs meeting ANSI A92.2

Hydraulic Design and Troubleshooting

IFPS - CFP Hydraulic Specialist Designing for mobile and industrial applications

Process Automation

IFPS - CFP Electronic Controls Specialist

Who We've Helped

Customers Reviews

Expertise

- Insulated Aerial Lift Design (A92.2)

- Mobile Elevated Platform Design (A92.20)

- Machine Design

- Hydraulic system design

- Hydraulic system troubleshooting

- Root Cause Diagnosis.

Services

- 3D CAD Modeling

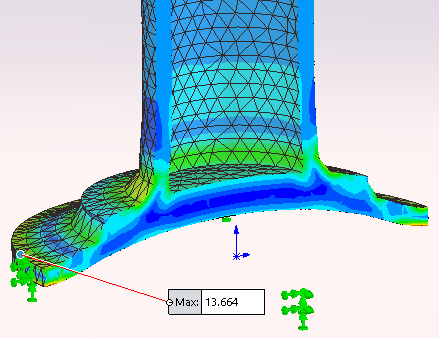

- Stress / Buckling Analysis

- Linear FEA Analysis (Solidworks Simulation)

- Conformance to sound design principles

- MathCAD and Excel based analysis of structures

Solid Modeling & Linear FEA

Solidworks and 2D AutoCAD

Solidworks Linear Simulation

Structural Design and Troubleshooting

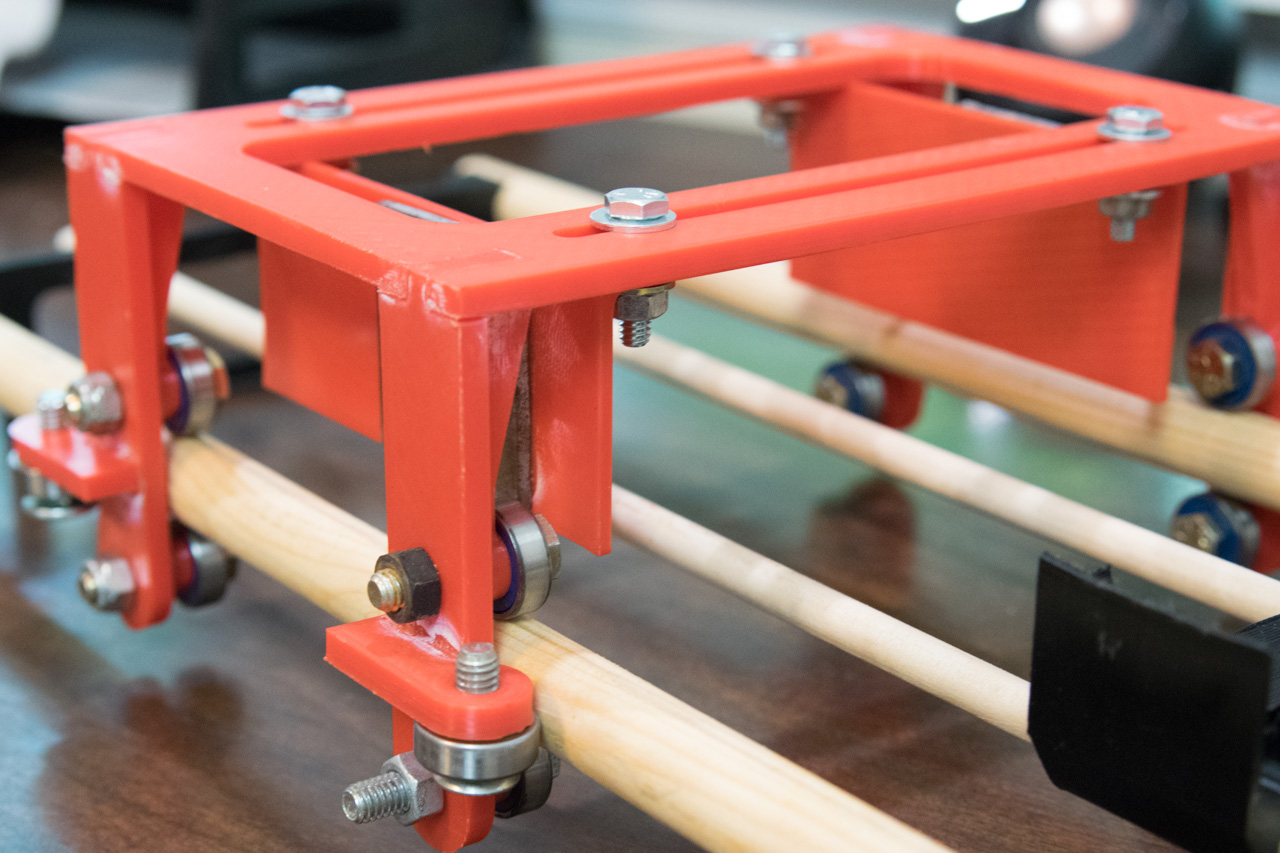

3D Printing and Prototyping

A design may look good in CAD, but often a proof of concept is needed.

Why Us?

Most engineers have neglected classical hand calculations and stress flow analysis in favor of the seemingly faster FEA process. True, FEA seems faster, but only if you designed it right to begin with. That never happens. Besides, FEA only shows you the hot spots, it cannot show you the solution.

Instead, using hand calculations as the primary design tool, combined with basic stress flow analysis, can eliminate the need for FEA in many cases. We still use FEA and are quite competent with it. However, we only use it as a check; thus saving time in the design process.

Media

Why Failure is Essential to Success

Recently, I was teaching a class of how life is like a pendulum where one side is failure and the other side is success. Most people live their life right in the middle with little to no movement on the pendulum. It’s comfortable there. It is impossible to enjoy great success without great failure as well.

The Mentored Engineer is a resource for mechanical engineers of all skill levels, but geared for young engineers just entering the work force. The material here will minimize the time needed to get an engineer competent in his or her field.

Come see the hundreds of articles and videos that have shaped the minds of many young engineers.Schedule Your Consultation

Let’s take a minute to see if Rasmussen Designs is a good partner for you. Click to get started.

Frequently Asked Questions

- Evaluate and eliminate stress issues without relying on FEA

- Diagnose mechanical and electrical issues quickly

- Proposing unique and cost effective retrofit solutions

- Bringing your idea from cocktail napkin sketch to reality

- Improving reliability and robustness of existing designs

- Hydraulic system design and troubleshooting

Engineering Experience

- Designed and managed over 20 large and small scale projects involving mobile and automation equipment

- Design and implement Data Acquisition Systems (DAQ) for testing apparatus

- Develop new manufacturing methods of fiberglass panels

- Finite Element Analysis for structural design and buckling

- Structural hand calculations

- Investigation of hydraulic, structural and electrical issues

- Design of various lifting equipment apparatus including energized electrical conductors

- Evaluation and design of industrial equipment structures

- Design of concrete slab moving equipment

Manufacturing Knowledge

Firm understanding of manufacturing process and fabrication techniques including:

- Plasma and laser cutting sheet steel cutting

- Brake press forming

- Roll forming

- Welding processes

- Controlling heat distortion

- Machining (CMC and manual)

- Filament wound composites

- Lean manufacturing

- Continuous improvement methods

Certifications

Professional Engineer

- North Carolina

- Texas

International Fluid Power Society

- Hydraulic Specialist (CFPHS)

- Electronic Controls Specialist (CFPESC)

Innovation

- 2 Patents Granted

- No-Tilt Dump Box (10,286,828)

- 4 Axis Insulated Joystick (10,707,869)

No!

The only exception would be if the scope changed. In that case, a new proposal will be provided for the additional work. Depending on the project, a portion of the existing project may be credited on the new proposal.

At Rasmussen Designs, we quote projects at fixed costs for your

benefit. Let’s face it, projects done on a time and materials budget

often end poorly when hours are running high. The desire to end the

project quickly grows and sometimes the parties never speak again. If

you have ever said to a contractor, “We’ll take care of it from here”

then you know exactly what I mean.

The main issues with time and material projects are

- Budget Overrun – In many projects, the end

can’t be seen from the beginning so projects are done on a Time & Materials (T & M)

basis. Complications from the real world kick in and the hours start

mounting. It’s only natural. - Lack of project scope

– When a consultant is getting paid by the hour, the natural tendency

is not to care about total project cost or the end goal. We will do

what you ask us to. This always leads to budget overrun. - More Extravagant Solutions Proposed

– If your project is done on T & M, the solutions will be larger

and more costly than you desire simply because the contractor will need

more time to implement the solution. - Lack of Innovation – When your contractor is being paid by the hour, there is no incentive to automate tasks or find creative solutions.

- Hesitation in making additional contact

– Let’s face it, we often hold back or hesitate before sending an email

or calling because we are afraid of the bill that follows.

None of these lead to a healthy working relationship. Let’s see how fixed costs change this working dynamic.

Budget overrun is eliminated because the work in the scope of the

project is a fixed cost. Whether the project takes us 20 hours or 2000

you pay the same amount. Undercharging is our problem, not yours.

In order to give an accurate bid, we will need to have a well defined

project scope. A well defined scope forces both parties to talk about

the end goals, project values and outcomes desired. Having these well

defined at the start of a project always leads to client satisfaction.

This also prevents overly extravagant proposals and replaces them with common sense solutions.

Fixed costs promote a partnership between the contractor and client. With a well defined scope and cost, a level of trust

develops between the parties because even if the project takes twice as

many hours to complete, it will cost the same. There will not be

tension if you believe that we are not as efficient as we should be and

think that we are “milking the clock.”

Finally, additional phone and email contact will be part of the

contract. We welcome you to share your thoughts and concerns about the

project without hesitation.

In many projects, I have looked back and said, “I wouldn’t imagine that the solution would look like this.” It is impossible to quote a fixed cost for the entire project when you can’t see what the end looks like from the beginning. Unfortunately, many projects switch to time and materials at this point.

But, let’s back up for a minute. We can definitely break up a project into sections that we could see the end from the beginning and quote each of those as fixed cost projects. For example, the first stage of a project could be simply to come up with 3 or 4 concepts that could solve the problem at hand. From there we could decide on one and develop if further.

I have found that most projects can be broken into the following stages; concepting, preliminary design, detailed design, final design and implementation. In each stage a clear scope and goal can be set and a fixed cost can be quoted. In each stage, it can be addressed if Rasmussen Designs is still the best candidate for the project. Often we are only needed for a few of the stages and will point you in the right direction.

For 3D CAD we use Solidworks and can use your version if it is still supported.

AutoCAD is used for 2D drawings of electrical and hydraulic schematics

MathCAD and MS Excel are used for hand calculations.

FEA is done with Solidworks Linear Simulation and is saved in the eDrawings format. A free reader is available online

Hiring an engineering consultant is stressful! How are you going to select the right one when your company is on the line. Here are ten things to consider before making a selection.